How to Select the Proper Gas Detector for Industrial and Home Safety?

Learn how to select the right gas detector for industrial and home safety by understanding sensor types, coverage needs, accuracy, and compliance standards.

Have you ever wondered to yourself whether you are breathing safe air or not? The hazardous potentially deadly invisible threats like carbon monoxide and natural gas tend to spread in colorless and odorless ways and cause death in a few minutes. The leaks of gases could have been stopped in just a single machine which is the reason why thousands of people were in hospitals annually.

A Gas Detector is not only a tool, but it is your 24/7 watchman. With the help of modern sensor technology, it is constantly tracking the quality of the air and sends instant notifications before the gas levels can cause serious health issues. It does not matter whether you are acquiring a family residence, a professional workroom or a large-scale industrial facility, this guide will assist you in choosing the appropriate type of detection system to ensure the safety of the most valuable items in your possession and that is, your people and your plant.

What Is a Gas Detector?

A Gas Detector is a smart safety gadget that will constantly check the air concerning the presence of dangerous gases and notify you immediately, when the dangerous concentrations are detected. These gadgets incorporate hi-tech sensor technology to detect a particular gas - carbon monoxide (CO), natural gas (methane), propane, hydrogen sulfide (H2S), lack of oxygen and many other toxic or flammable gases and give advance warning before the quantity becomes dangerous or hazardous.

Gas detectors are also vital in residential as well as industrial safety unlike smoke detectors which are only sensitive to fire and therefore gas detectors are needed in homes to check the presence of invisible dangers that lack smell, color, and immediate symptoms.

How Gas Detectors Work: 24/7 Silent Protection.

The operation of a gas detector is sophisticated yet reliable:

Sensors Monitor Air Quality Continuously

Gas detectors have special sensors such as electrochemical sensors, catalytic sensors, infrared sensors, and semiconductor sensors that continuously sample the air around it and quantify the gas concentrations in parts per million (PPM) or percentage of Lower Explosive Limit (LEL).

Detection Technology Identifies Specific Gases

Various types of sensors are used to work with distinct gases. Carbon monoxide and hydrogen sulfide are examples of toxic gases that are detected by electrochemical sensors. Sensors detecting combustible gases such as methane and propane are catalytic. IR sensors are used to measure such gases as carbon dioxide without making physical contact.

Real-Time Analysis and Processing

The microprocessor used in the detector will always be looking at sensor readings and compare them to pre-programmed safety thresholds as well as compensate by environmental influences such as temperature and humidity.

Instant Alerts When Danger Detected

Once the gas concentration reaches intolerable levels, the detector automatically triggers several warning mechanisms: loud alarms (85-120 decibels), flashing LED displays, digital display messages, and in smart models, smartphone messages or integration with building safety systems.

Example: In the evening, a faulty furnace starts giving out carbon monoxide. When your family is asleep, the electrochemical sensor in the gas detector will detect an increase in the CO levels. By the time the concentrations get to dangerous levels, everyone is woken by piercing alarms, the digital readout displays CO - 50 PPM and you have time to get out of the house and open the house to air.

Gas Detector Types: Selecting the Level of Protection.

Gas detectors are available in many different configurations tailored to different settings and gases:

Portable Gas Detectors

Small, battery-powered portable gas detectors carried by the workers or taken to other places. Critical to the entry of confined spaces, maintenance operations, emergency response operation and other situations that demand mobility whilst ensuring gas monitoring protection.

Explosion-proof Gas Detectors

Explosion Proof Gas Detection Explosion proof gas detectors are specifically designed to work in dangerous areas where there might be a flammable gas or vapour. They are impregnable and have strong design that eliminates the chances of ignition, thus they are used in oil and gas plants, chemical plants and other industrial locations that are very hazardous.

Fixed Gas Detectors

Installed permanently in a certain place such as boiler rooms, kitchens, garages, warehouses or manufactories. They are able to offer 24/7 surveillance in areas of interest and may be linked to building control or alarm systems.

Why Choose a Gas Detector Over Relying on Your Senses?

Human senses cannot be helpful in detecting harmful gases. Most of the lethal gases are not odorous and are colorless and have no immediate effects until the concentration becomes harmful. Gas detectors are not only scientifically accurate but also real time and life saving.

Benefits for Your Home and Workplace

Gas Detector provides a complete protection:

Stops furnaces, water heaters, generators and vehicle exhaust carbon monoxide poisoning.

Identifies the natural gas leakages before they become explosive or dangerous in terms of fire.

Measures oxygen levels within a confined space to eliminate asphyxiation.

Determines industrial gases that are toxic such as hydrogen sulfide, ammonia, chlorine, and volatile organic compounds.

Offers 24/7 surveillance during the time that you are asleep or when nobody is around.

Provides relief to families, particularly those who have children, elderly or people with respiratory issues.

Assures regulatory compliance of industrial, commercial and healthcare premises.

Limits the liability of owners of businesses by showing positive safety practices.

Early warning is a life-saving measure that prevents the onset of the symptoms or explosions.

How to Choose the Best Gas Detector

The choice of the right gas detector is the surest way to protect yourself in the environment and risks specific to your case:

1. Identify Your Gas Hazards

Identify gases in your surroundings. Houses usually require carbon monoxide and natural gas sensors. The processes at industrial facilities need detectors unique to those processes: refineries have to have hydrocarbon detectors, wastewater plants must have H2S detectors, laboratories will need a variety of toxic gas sensors.

2. Determine Single or Multi Gas Need

Single gas detectors are reliable and economical in residential applications or in the event of single known hazards. In industrially related situations, where space is limited, or there are numerous sources of potential gases, multi-gas detectors are recommended to cover the entire area.

3. Choose Fixed or Portable Configuration

Permanent monitoring of given areas such as boiler rooms, parking garages, kitchens or production areas is best suited to the use of fixed detectors. Portable detectors are necessary where the workers are entering confined areas, doing maintenance or changing between various areas of hazard.

4. Consider Detection Range and Accuracy

Test the specifications of the detector, its range of measurement, and its accuracy. In industry, it can be necessary to make some measurements at very low PPM levels of toxic gases or very accurate LEL measurements of combustible gases. Check that the detector scans the concentration ranges of your application.

5. Evaluate Alarm Systems and Outputs

Quality detectors are available with various types of alarms, such as audible (85-120 dB) and visual (blinking LEDs) and vibrating alarm in noisy working conditions. Relay outputs should be provided as an input or output in the industrial models to connect with the building system, ventilation system or emergency shutdown system.

6. Assess Battery Life and Power Options

Minimum continuous operation of portable detectors should be 1224 hours. Look at the rechargeable and replaceable batteries depending on usage patterns. Fixed detectors are normally supplied by AC power with a battery backup to prevent unexpected stopping when power goes down.

7. Verify Sensor Lifespan and Calibration

Various sensor technologies have a different life expectancy as an electrochemical sensor has a life expectancy of 2-3 years, catalytic sensor 3-5 years, the infrared sensor has a life expectancy of 5-10 years. Select those detectors whose calibration processes are not very complex and whose overall ownership costs including sensor replacement.

8. Smart Features and Connectivity

Contemporary types of detectors provide Wi-Fi capabilities, smartphone applications, data recording, remote access, and support of smart home or building management systems. These capabilities promote safety by notifying instantly and analyzing trends in the past.

What Are the Applications of Gas Detectors?

Gas sensors will offer essential security in a wide range of settings:

Residential Homes: furnace, water heater, fireplace, Carbon monoxide; natural gas leakage in kitchen and basement; bedroom and living rooms protection.

Commercial Buildings: Parking garage ventilation control; restaurant kitchen safety; hotel boiler rooms; shopping mall maintenance area; office building mechanical room

Industrial Facilities: chemical plants that check exposure to toxic gases; refineries that check the leakage of hydrocarbons; manufacturing plants that check the gasses released in the processes; power plants that check the systems of combustion.

Constrained Areas: Tank entry safety; sewer and manhole work; ship holds and cargo spaces; underground vaults; storage silos.

Oil and Gas: Drilling rigs safety; pipeline leakages; refinery processes; tank farms; offshore platforms.

Wastewater Treatment: Hydrogen sulfide testing in treatment plants; confined space access in the treatment plant; pump station safety, sludge processing area.

Laboratories: Chemical fume hoods; gas cylinder warehouses; research centers dealing with hazardous chemicals; college chemistry departments.

Healthcare Facilities: monitoring of medical gas storage; ethylene oxide sterilization area; laboratory safety; oxygen monitoring in MRI room.

Agriculture: Monitoring of grain silos with oxygen deficiency and dust explosions; storage of manure H2S; in the greenhouse CO2 monitoring; in the fumigation safety.

Hospitality & Food Service: monitoring gas appliances in commercial kitchens; restaurant safety; hotel mechanical system; food processing facilities.

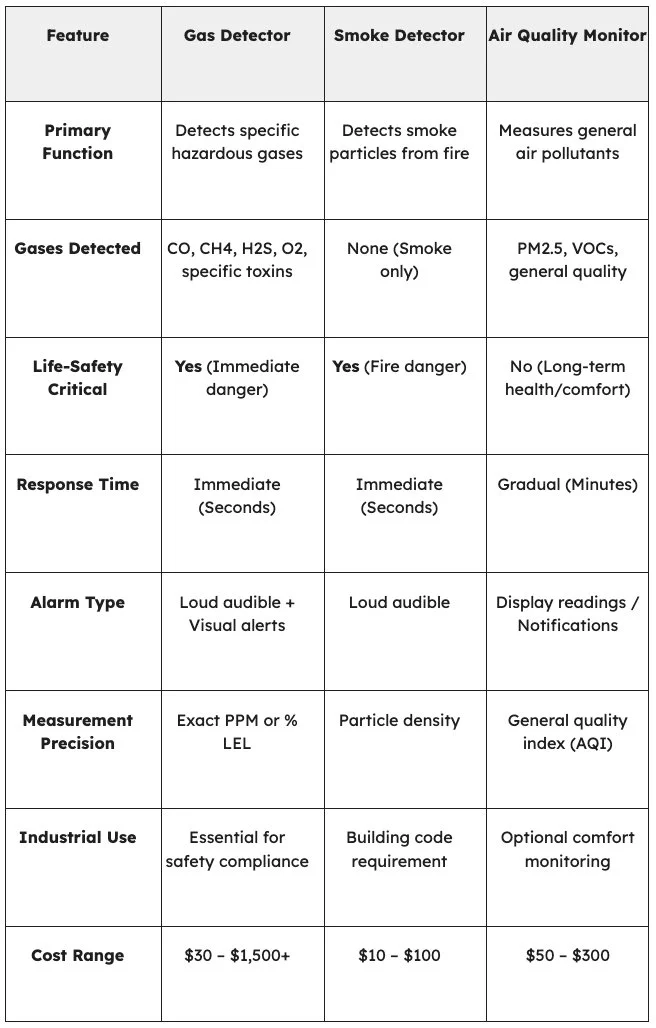

Gas Detector vs. Smoke Detector vs. Air Quality Monitor

Installation Tips

Gas detectors are to be installed properly: this guarantees readings and provides protection:

For Carbon Monoxide Detectors

Height: Place on the wall at breathing level (5-6 feet high) or according to directions provided by the manufacturer.

Location: Position close to sleeping quarters, on every floor of house, to burning appliances (but may not be within 15 feet to prevent false alarms)

Avoid: Do not put in close to windows, doors or vents where readings can be influenced by drafts.

For Natural Gas/Methane Detectors

Height: Mount close to ceiling because methane moves upwards (between 6-12 inches of ceiling)

Location:Close to gas appliances, water heaters, furnaces and gas lines.

Coverage: 1 detector per floor and more in kitchens and utility rooms.

For Propane/LPG Detectors

Height: It should be installed close to the floor (6-12 inches above floor) as propane sinks.

Location: Propane tanks, appliances, and possible sources of leakages are nearby.

Basements: Necessary in basement spaces that are prone to heavy gasses.

For Industrial Fixed Detectors

Strategic Location: The most probable location of gas releases - close to valves, connections, process equipment, entrance to confined spaces.

Pattern of coverage: Go by the patterns of gas dispersion; put into consideration airflow, ventilation and target gas density.

Accessibility: Mount at a safe location where maintenance and calibration can be done.

Environmental Protection: Have outdoor installations and a harsh environment in weatherproof housings.

Connection: Interconnect to building management system, ventilating control, or emergency shutdown control system.

General Installation Best Practices

Always follow instructions of the manufacturers fully before installation.

Immediately install test detectors.

Do not leave in damp places (bathrooms) unless indicated to be compatible.

Record date of detector maintenance.

Have audible alarms in areas of protection.

Maintenance and Calibration

To maintain gas detectors in proper operation, it is necessary to maintain them:

Monthly Testing

Test button: Press test button to check alarm functionality. Audible and visual alarms must start off. In case of weak or delayed response, examine check batteries or change units.

Battery Replacement

Change the batteries once a year or when the warning of low battery is on, whichever occurs first. Only the recommended battery types are to be used. Do not turn off detectors because of battery charges, lives require constant use.

Sensor Inspection

Ensure sensor vents are free and clear. Sensors can be blocked by dust, grease, or paint and this could give wrong readings. Vacuum or clean gently following the directions of the manufacturer.

Calibration Schedule

Portable and industrial detectors should have regular calibration with certified test gases. Housing units are usually not to be calibrated, they usually need to be changed according to the suggestions of the manufacturers (a standard of 5-7 years of CO detector is typical).

Calibration Process (Industrial Detectors)

Bump test weekly with target gas and check sensor response.

Calibrate the full condition monthly or in accordance with the regulatory requirements.

Test with known concentration certified calibration gases.

Record every calibration process in compliance records.

The sensors that do not calibrate or react slowly should be replaced.

Record Keeping

Keep records of testing, calibration, battery change and sensor replacement. The documentation is used to show compliance at the time of inspection and to determine the pattern that can point to an environmental problem.

Environmental Considerations

Sensor performance can be influenced by extreme temperatures, high humidity, solvent exposure or silicone compounds. Attach detectors to suitable environmental conditions and install weatherproof models where needed.

Replacement Schedule

Sensors deteriorate even when they are well maintained. Change detectors as per the manufacturer schedules 5-7 years in residential, 2-5 years in industrial electrochemical sensors but the infrared sensors can be longer.

Advanced Features in Modern Gas Detectors

The gas detectors on the market today have an element of smart technology, which brings them a high level of safety and convenience:

Digital Display with Real-Time Readings

LCD displays display the precise gas concentrations in either PPM or percent LEL, peak exposures, battery, and sensor conditions. This data is useful to evaluate severity and make informed decisions in case of an emergency.

Data Logging and Historical Tracking

Advanced detectors trace gas exposure through time producing detailed logs that can be used to identify trends, investigate incidents, prove compliance and detect chronic low level exposures which would otherwise remain undetected.

Wireless Connectivity and Smart Alerts

The detectors with Wi-Fi or Bluetooth can provide instant messages to smartphones when the gas is detected to monitor the vacation homes remotely to ensure the homes can be safe even when people are away and to respond to emergency situations faster.

Multi Sensor Arrays

Multi-sensor detectors use several sensors of the same gas, which has a redundancy and cross verification capability to achieve elimination of false alarms and real threats will never be overlooked.

Adjustable Alarm Thresholds

Industrial models enable alarm levels to be customized with low alarms being set to provide a warning, high alarms to signal immediate danger, TWA (time-weighted average) alarms to give a cumulative exposure, and STEL (short-term exposure limit) alarms.

Man Down and Motion Detection

The portable detectors have safety features such as motion sensors which send out an alarm in case the wearer is incapacitated, tilt sensors and emergency panic buttons.

Integrated GPS Location Tracking

In the case of portable units that may be deployed in a large facility or even at a number of sites, GPS tracking will help determine where the alarms are activated and respond to an emergency much faster and find the workers in need of help.

Automated Ventilation Control

Fixed detectors may also couple with HVAC systems, turning on exhaust fans or fresh air intake into the building in case dangerous gases are detected, but it is able to clear the air before it becomes dangerous.

Common Mistakes to Avoid

Wrong Gas Detection Technology: This is the technique of monitoring the gas of poisonous nature by making use of a combustible gas detector or the other way round. Every type of sensor senses a particular type of gas to make sure that your sensor corresponds with the hazards you are dealing with.

Inappropriate Height of installation Height: It is pointless to install methane detectors low or propane detectors on high. The denser the gas, the higher it should be mounted.

Neglect of Calibration Requirements: Accuracy of industrial detectors decreases with time. Passwords that skip calibration will provide a false sense of security and expose you.

Delaying Battery Replacement: Crippled or chirping detectors have no protection. Change batteries as soon as the warning signs of low batteries are turned on.

Ignoring Sensor Expiration: There is a finite lifetime of sensors. It is risky to use detectors that have used-up sensors as they might fail to work in real emergencies.

Installation of Too Few Detectors: In single level homes and large plants, a single detector is insufficient. Provide appropriate coverage depending on the size of the area and the places of gas hazards.

Painting Over Detectors: Coat sensor vents, keep gas off sensing elements. Do not paint detectors or venting.

False Positive Overlooking Alarms: It is imperative to check out all the alarms. Ignoring alarms as false makes it easy to become complacent and in the event of a real emergency, this complacency may cost lives.

Obstructing Sensor Vents: Blocking the sensors by placing furniture, decorations or equipment in front of detectors does not allow gas to get to the sensors making them useless.

Wrong Environments: Standard detectors cannot operate in hot environments or at the explosive limit. Application of certified, environment friendly models.

Sum up

A gas detector is not just a compliance issue, but an investment and effort to save human lives against the unseen, unreliable attack. These tools can be seen either as the home carbon monoxide detector or the 24/7 guardian and watcher of the complicated industrial leaks.

You have a strong foundation of safety by choosing the correct sensor to match your hazards and by making sure you have the correct calibration. Early warning gives the required few seconds of evacuation and emergency response. When it comes to industrial and home safety, you can never be sure when your guardian angel will look after you so the best bet is to be prepared when you cannot see. Get certified security now and make sure that invisible does not mean unsecured.